Nano Overload Warning System – NOWS

Nano Overload Warning System – NOWS

The lineGrip nano is equipped with a unique safety warning system – called NOWS – that lets you detect crucial overloading of the nano.

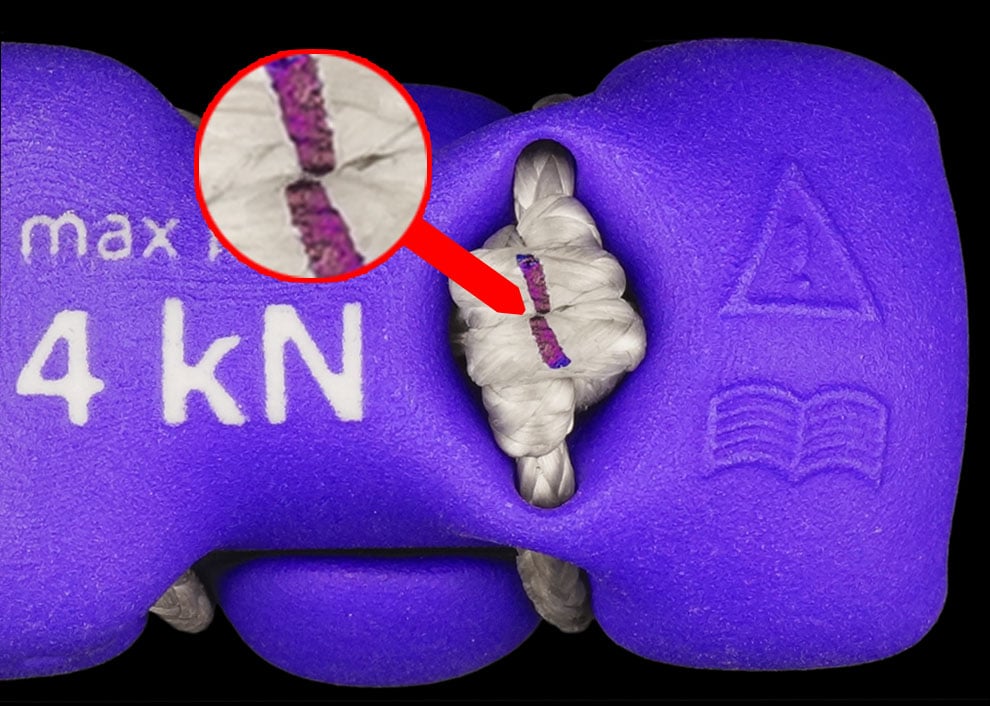

The NOWS consists of a special knot at the bottom of the nano, which will slowly begin to slip at about 5-6kN load. By means of a marker on the knot you can detect this slipping through a gradual separation of the marker.

IMPORTANT! The NOWS is an overload warning, NOT a max. load indicator!

A separating overload marker means that you have already dangerously overloaded the nano.

Do NOT increase tension until the marker separates!

Always monitor the tension and do NOT exceed 4kN load!

This image shows an intact NOWS knot at the top and an overloaded NOWS at the bottom, with a separated marker after the nano has been loaded with 5kN (i.e. after 1kN overload).

Please note: the distance of separation of the markers does not reliably indicate the range/degree of overload!

As a rule of thumb, the dyneema cord should be replaced and the NOWS knot exactly calibrated, after the marker has separated more than 3-4mm. This is the only way to restore a reliable overload warning system.

Please be aware: a separated NOWS can not be reset once it has been overloaded!

A marker can be re-drawn after it has been separated, but be aware that the NOWS will now be set to the last load value!

Example: The original marker separated significantly because the nano was used at 6kN.

If the marker is re-drawn now, it will separate above 6kN next time!

Therefore this NOWS marker will now engage at a dangerously high load!!!

After intensive use a minimal misalignment might occur, even if you never overloaded the nano. This comes from further setting of the knot during the first 20-30 load cycles. The markers should not fully separate though.

In the beginning, after multiple use, a separation as seen in the magnification on this image is normal and absolutely acceptable.

A separation as seen in the previous image (above section), indicates severe overloading with more than 1kN!

The cord tails behind the NOWS knot are threaded inside the nano body. About 40-50mm of extra cord is stored in the nano’s cord cavities.

If you ever overload your nano and the markers separate even by more than 10mm, such that the markers disappear inside the knot, there is still no worry about the knot ever coming undone due to the long tail ends inside the nano.

We will re-thread your nano anytime with a new dyneema cord and calibrate a new NOWS knot for a net cost price of about 10€ + return shipping.

Every nano is manually threaded, knotted and then individually tested to 4.5kN during the NOWS calibration. After calibration the nano is unloaded, left to rest, and then loaded with 4.5kN reference load again to ensure proper setting of the knot.

After setting and calibration, a surface sealant is applied to the knot, and the NOWS marking is added. Now the nano is ready for shipping.